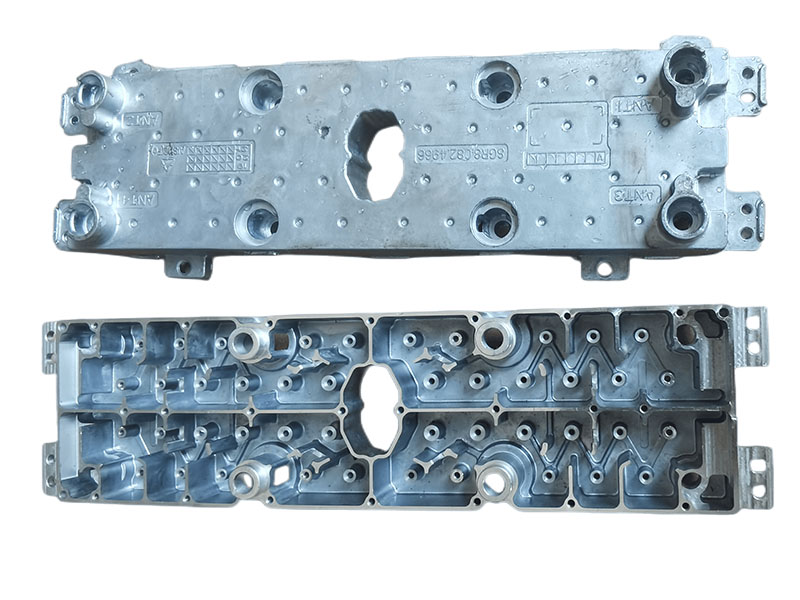

Aluminum Die Casting

Class-A Surfaces – We have mastered the design and manufacture of parts with automotive class-A surfaces which can be mirror chromed or painted.

Weight reduction – Aluminum die casting provides an optimal balance of strength, weight and cost making in excellent material for weight sensitive applications requiring durability and strength.

Dimensional accuracy and stability – Aluminum casting produces parts that are durable,stable and keeping close tolerances.

High-speed production – Aluminum die casting provides complex shapes,well tolerances than a lot of other mass production processes. Few or no machining is required to produce thousands of identical castings.

Heat Dispersion – Die cast aluminum have both the dimensional flexibility and heat dispersion characteristics.

Heat Tolerance – Die cast parts can match the complexity found in over-mold plastics while operating effectively in high heat situation.

Strength and weight – Pressure cast aluminum parts provide well strength than plastic injection molding for the same dimensions.

Multiple finishing techniques – FUERD provide aluminum die cast parts with smooth or textured surfaces which can easily be plated, coated or finished with a minimum of surface preparation.

Simplified Assembly – Aluminum die castings can be integral fastening elements, such as bosses and studs. Integration of threads in the mold design phase eliminates additional fasteners on assembly processes. Integrated tabs and bosses and registration features further reduces part count and well assembly quality.

Alloy Selection – Selecting the right aluminum alloy for the application and designing the component to exploit the characteristics of the alloy and the die cast process allows OEMs to reap the full benefits of aluminum in many applications, such as A360, A380, ACD12.

Corrosion Resistance – Aluminum offers distinct advantages over alternative materials, in applications demanding a high tolerance to corrosive environments. Aluminum parts provide the best combined durability against salt, water and UV, when combined with the correct coating technology for the application – damage.